We can offer you

- High quality and durable products

- Tools proven by work with my own Rottler/Sunnen/AMC Schou/AZ/Serdi equipment

- Any customized tool according to your drawings

- Chinese factory production

Nine years on

-

37,00 € Add to cart

37,00 € Add to cart001168 set of 2 (30deg-2.5) valve seat cutting carbide bits NEWEN SERDI ROTTLER

15.0 -

87,00 € Add to cart

87,00 € Add to cart1/2 ” PCD RNMN 1203 Insert 3.18 mm width for Rottler Serdi Berco fits RNMN/RNGN 6303P

15.0 -

92,00 € Add to cart

92,00 € Add to cart1/2 ” PCD RNMN 1204 Insert 4,76 width for Rottler Serdi Berco fits RNMN/RNGN

-

87,00 € Add to cart

87,00 € Add to cart1/2″ CBN Insert 6303Q for Rottler Serdi Berco Sunnen RNMN 1204 fits RNMN/RNGN 6303Q

Tools for honing machines

At Pausnop, we pride ourselves on being a leading supplier of high-quality tools for honing machines. Our commitment to excellence and precision drives us to provide our customers with the best products in the industry. Whether you are a small workshop or an enterprise, our tools are designed to meet your honing needs with unmatched performance and reliability.

We offer a comprehensive range of aftermarket tools for honing machines, each meticulously crafted to ensure optimal performance and durability.

Honing stones for mandrels

Honing stones for mandrels

Sunnen and Rottler honing stones are made from diamonds, Polycrystalline Diamond (PCD), borazon (CBN), abrasive: aluminum-oxide, silicon carbide by any grit 80/120/150 /220 /280/500/600 and length 2, 3, 3 1/2, 4 inches 50,76,89,104 mm. They are meticulously engineered to deliver superior cutting action, ensuring that your machining processes are both efficient and effective. With a focus on durability, these honing stones maintain their sharpness over extended periods, reducing the need for frequent replacements and minimizing downtime in your operations. Their advanced composition allows for optimal material removal rates, making them an excellent choice for a wide range of industrial applications.

Honing stones are intended for equopment such as Rottler vertical honing machines HP6A, HP7A, H85A, H85AX, H85AXY, H86A, H86AX, H86AXY, H87AXY;

and for Sunnen vertical honing machines CV 616, SV-15, SV-35, SV-2400, SV-2500, SV-3000, SV-3100, SV-2010, CK-10, CK-21 and horizontal honing machines CH-100, SSH-1680, SH-2000, SH-4000, SH-5000, SH-6000.

Precision is at the heart of these honing stones design. They are ideal for applications requiring tight tolerances and exacting surface finishes. By incorporating our honing stones into your machining processes, you can trust that your final products will meet the highest standards of quality and accuracy, ultimately enhancing your productivity and competitive edge.

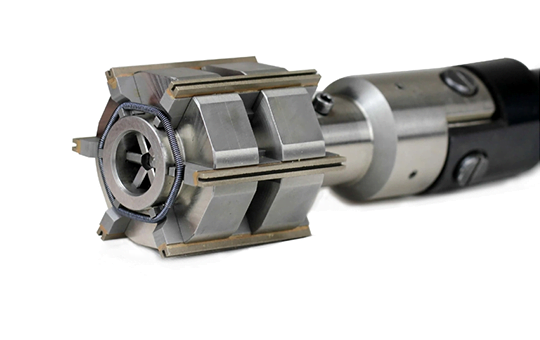

Honing mandrels

We supply robust and reliable mandrels that are essential for holding and rotating honing stones, playing a critical role in achieving precise machining results. Presented mandrels are designed with superior materials and craftsmanship to withstand the rigors of continuous use, ensuring they remain dependable and stable over time. The strength and durability of mandrels in stock minimize the risk of deformation or failure, even under high-stress conditions, providing a secure and consistent platform for your honing stones. This reliability is key to maintaining the accuracy and quality of your machining processes.

Honing heads

Honing heads, precision honing heads, honing sleeves on sale are engineered to deliver exceptional accuracy and consistency. They are available in various sizes and configurations to suit different honing applications and machine types.

We produce a lot of customized replacement honing drives, drive shafts, connecting rods, honing heads for Sunnen CV 616 Rottler style designed for 6 pcs Diamond or CBN honing stones.

In addition to honing stones, mandrels, and heads, we offer a variety of other essential tools and accessories. These include adapters, holders, and specialized equipment to enhance your honing setup and maximize productivity.

Grinding wheels for crankshaft

Grinding wheels for crankshaft

Grinding wheels for crankshaft grinding machines are specialized tools designed to efficiently grind and shape the crankshaft’s journals and shoulders to achieve precise dimensions and smooth finishes. These wheels are typically made from high-quality abrasive materials like aluminum oxide or silicon carbide, which offer excellent durability and cutting performance.

Key features of our grinding wheels for crankshaft grinding machines include:

Precision Bonding. The bonding material is engineered to maintain wheel integrity while providing the necessary hardness and toughness for crankshaft grinding.

Shape and Size. These wheels come in various shapes and sizes to accommodate different crankshaft geometries and machine specifications.

Grinding Performance. Designed to produce minimal vibration, ensuring smooth, accurate grinding and reducing the risk of damage to the crankshaft.

Coolant Compatibility. Compatible with various coolants to reduce heat generation, preventing thermal damage and ensuring a superior surface finish.

Customization. Can be tailored to specific applications, including different abrasive grains and grit sizes, to meet particular grinding requirements.

These grinding wheels are crucial for achieving the desired surface finish, dimensional accuracy, and extended lifespan of crankshafts in automotive and industrial applications.

Stone holders

Stone holders for Rottler, Sunnen vertical horizontal honing machines are precision-engineered components designed to securely hold abrasive, diamond, CBN stones during the honing process. These holders ensure that the honing stones are properly aligned and maintained at the correct angle and pressure, allowing for consistent and accurate material removal. They are typically constructed from high-quality materials to withstand the rigorous demands of honing operations and to provide long-lasting durability. The design of the stone holders allows for easy installation and replacement of honing stones, facilitating efficient and effective honing of engine cylinders and other cylindrical components.

We understand the importance of compatibility and versatility in honing operations. That’s why we offer tools that are designed to work seamlessly with renowned honing machine brands such as:

Quality honing tools

We are dedicated to providing products that meet the highest standards of quality and performance. Each tool is rigorously tested to ensure it meets our stringent criteria.

We believe that top-quality tools should be accessible to all. That’s why we offer used products at competitive prices, providing excellent value without compromising on quality.

Our team of experts is always ready to assist you with any queries or technical support you may need. We are committed to helping you find the right tools for your specific requirements.

We offer free worldwide shipping on orders over 50 euros, making it easy for you to access our products no matter where you are located.

Contact Us

If you have any questions or need further information about our products, please do not hesitate to contact us. Our dedicated customer service team is here to assist you and ensure you find the perfect solutions for your honing needs.

Honing stones for mandrels

Honing stones for mandrels Grinding wheels for crankshaft

Grinding wheels for crankshaft